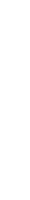

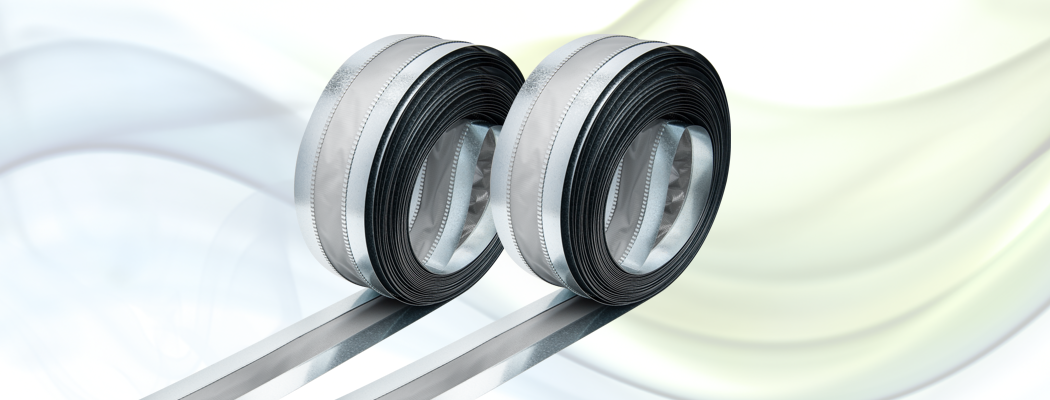

DEC Connector

The flexible connection DEC Connector has been manufactured out of an already existing steel-to-fabric-to-steel connection, which enables a fast and simple connection between two (rigid) ducts. Once the galvanized steel overlap has been bent into the correct shape it can be fastened with self drilling screws, pop rivets or spot welding. The result is a solid flexible connection which can be mounted simply and quickly. It meets the constructional demands.

By default the DEC Connector will be delivered with a vinyl fabric. Neopreen, polyurethane and silicone are available on request. Each type of fabric has its own qualities and specific application.

DEC Connector type VINYL: copolymer coated polyester

The fabric with a copolymer coating used in this type, is suitable for applications with high requirements to the moisture resistance and less or no mechanical requirements. This connector is appropriate for round, oval and rectangular air ducts. It can be shaped easily with a minimal percentage of waste. Excellent mechanical resistance. High abrasion resistance. All purpose fabric.

DEC Connector type SILICONE: silicon coated glass fibre

The fabric with a silicone coating used in this type of connector, is suitable for applications with high mechanical demands to the material. This connector is appropriate for round, oval and rectangular air ducts. It can be shaped easily with a minimal percentage of waste. Excellent temperature resistancy, Low smoke emission and a very good chemical resistance.

DEC Connector type POLYURETHANE: polyurethane coated glass fibre

The fabric with a polyurethane coating used in this type of connector, is suitable for applications were a high chemical resistance is required. This connector is appropriate for round, oval and rectangular air ducts. It can be shaped easily with a minimal percentage of waste. Very good temperature resistancy and M0-400°C/2H classified.

DEC Connector type NEOPRENE: neoprene coated glass fibre

The fabric with a neoprene coating used in this type of connector, is suitable for applications were a high chemical resistance is required. This connector is appropriate for round, oval and rectangular air ducts. It can be shaped easily with a minimal percentage of waste. General purpose fabric, excellent mechanical resistance and very good chemical resistance.

|

Spécifications bande d'acier |

|

|---|---|

| matériel bande d'acier: | tôle d'acier galvanisé |

épaisseur: |

400 micron |

tolérance d'épaisseur: |

± 50 micron |

poids de zinc: |

275 g/m² |

qualité: |

STO2Z275 |

réactifs chromatiques: |

NA Quality llA |

|

Spécifications vinyle |

|

|---|---|

| poids spécifique: | 600 gr/m² |

| tenue en température: | -30 °C à 70 °C |

| couleur: | gris foncé |

|

Spécifications polyuréthane |

|

|---|---|

| poids spécifique: | 450 gr/m² |

| tenue en température: | -50 °C à 200 °C |

valeur maximale: |

400 °C pour 2 heures |

| couleur: | argent |

|

Spécifications silicone |

|

|---|---|

| poids spécifique: | 550 gr/m² |

| tenue en température: | -40 °C à 280 °C |

| couleur: | argent |

|

Spécifications néoprène |

|

|---|---|

| poids spécifique: | 570 gr/m² |

| tenue en température: | -30 °C à 100 °C |

| couleur: | noir |

|

Spécifications techniques

|

|

|---|---|

Spécification Néerlandaise |

|

Spécification Allemande |

|

Spécification Anglaise |

|

Images de produits

|

|

|---|---|

|

Certificats polyuréthane |

||

|---|---|---|

Royaume-Uni |

BS476 | Part 7 Class 1 |

France |

NF | M0 |

|

Certificats silicone |

||

|---|---|---|

Royaume-Uni |

BS476 | Part 7 Class 1 |

France |

NF | M1/M0 |

|

|

|

|

|

|---|---|---|---|---|

| 35x060x35 | 25 mtr | HCM35060/25 | 1 | n.a. |

| 45x060x45 | 25 mtr | HCM45060/25 | 1 | 56 |

| 45x075x45 | 25 mtr | HCM45075/25 | 1 | 46 |

| 70x100x70 | 25 mtr | HCM70100/25 | 1 | 32 |

M (material code): V = vinyl, S = silicon, P = polyurethane and N = neoprene